Overview: Integral Product Design Process

This academic case study showcases the end-to-end development of a functional Physical Product, a functional Bluetooth speaker prototype. The process involved all stages, from sketching to prototyping, including creating an early-stage foam model to validate product ergonomics and component capacity, ensuring manufacturing feasibility before production. The resulting design includes a distinct two-part enclosure: a matte black base housing the connectivity and controls, and a conical silver aluminum enclosure, focusing on minimalist aesthetics.

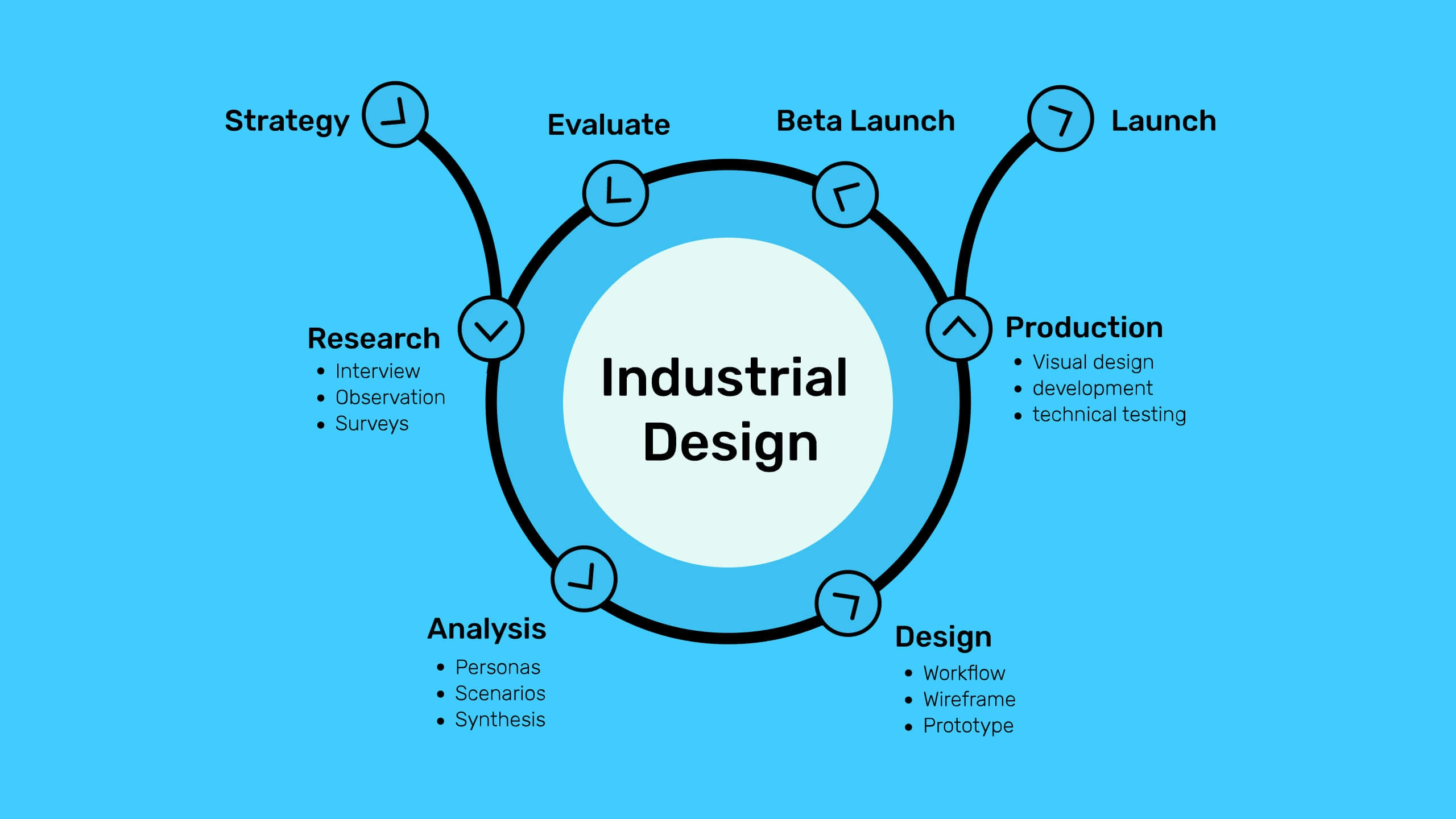

The Process: A Systemic Development Approach

- Research & Concept Ideation

- Ergonomics & Capacity Validation

- Detail Design & 3D Modelling

- Functional Prototyping & CMF Application

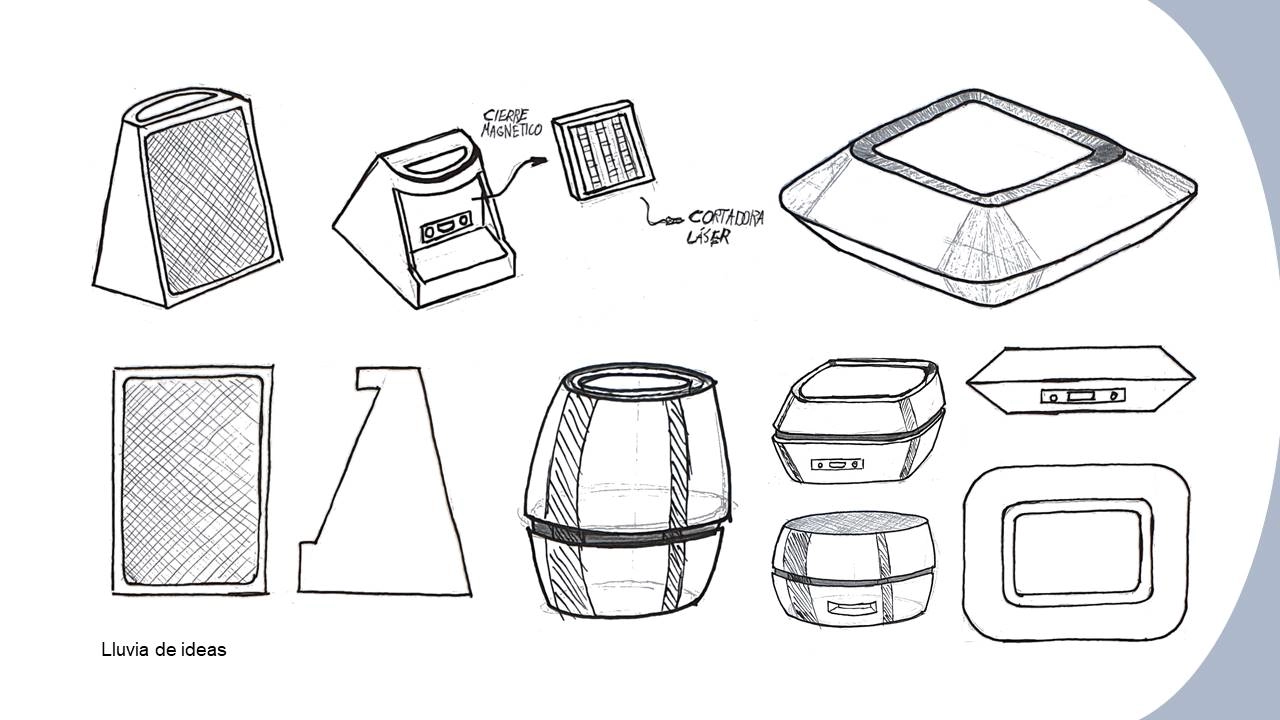

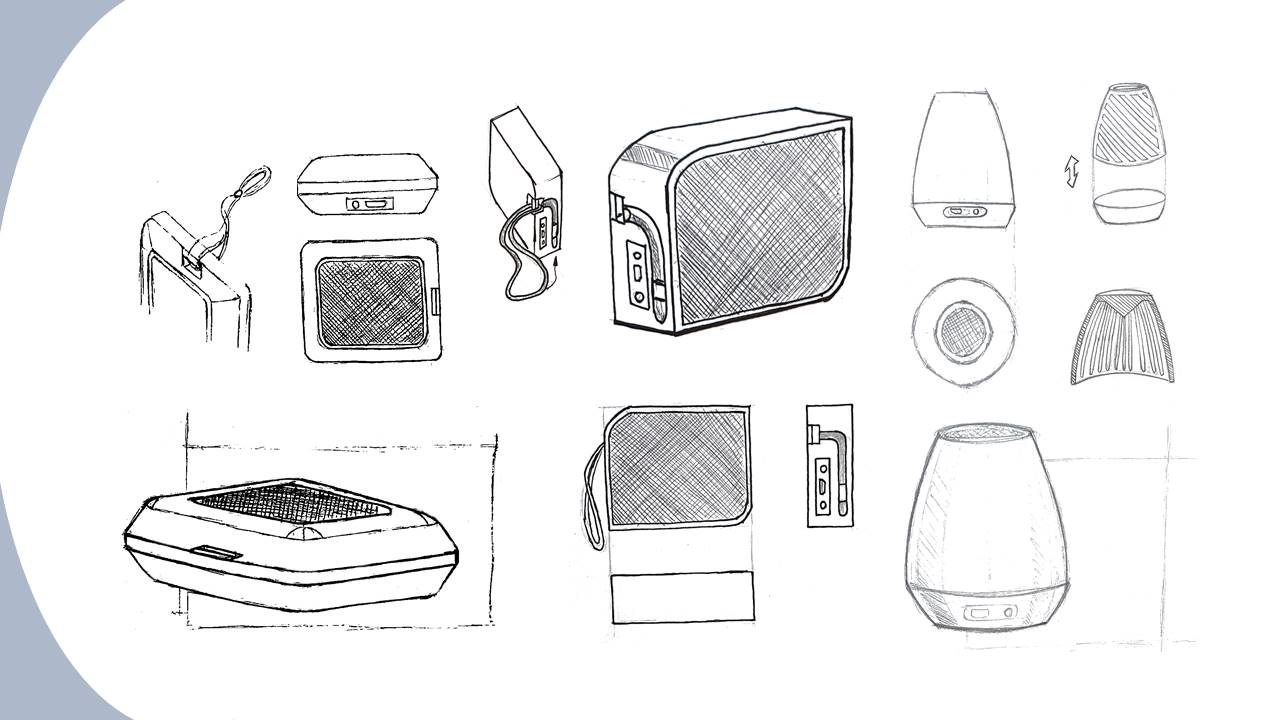

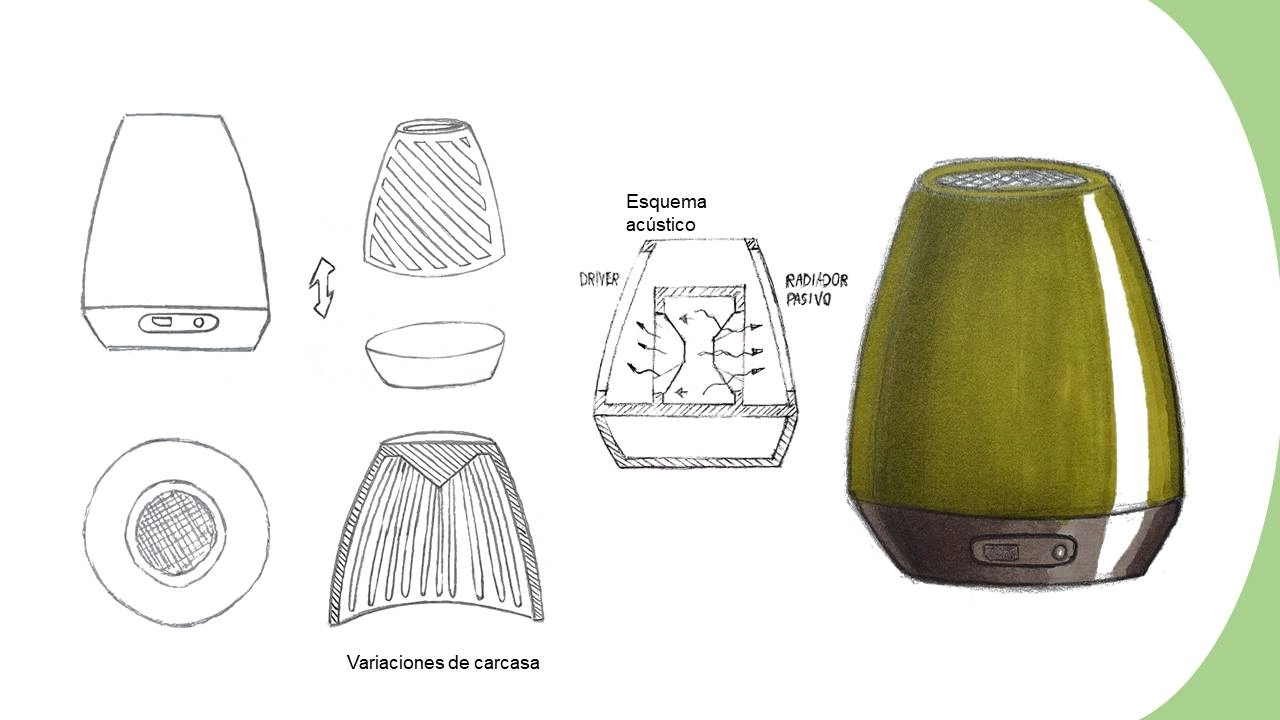

1. Research & Concept Ideation

Market landscape and moodboard ideation were used to define the aesthetic and functional design. This was followed by an intensive exploration of geometries via sketching to establish the product's foundational form factor.

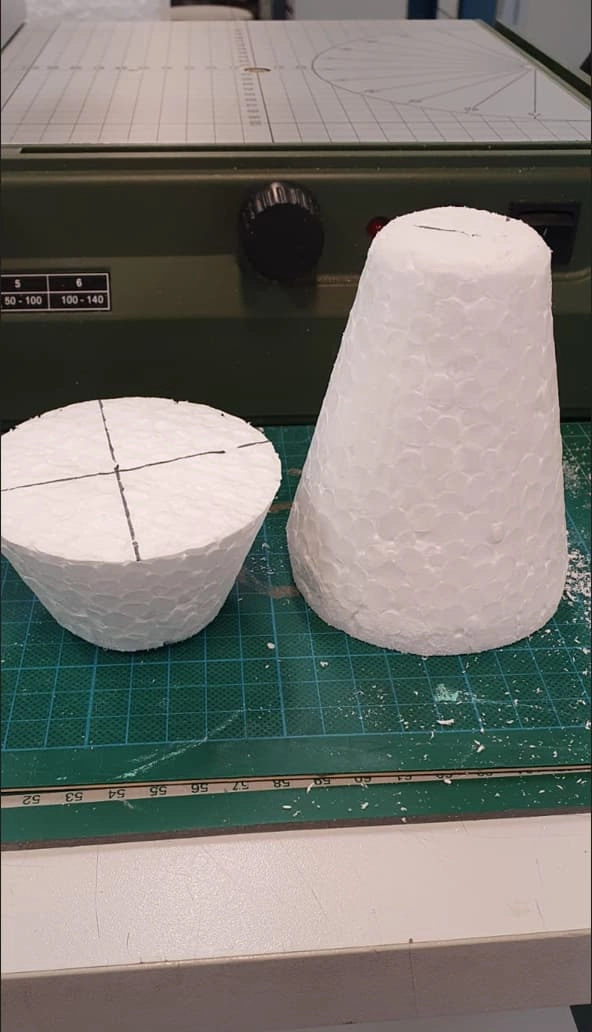

2. Ergonomics & Capacity Validation

Creation of a low-fidelity prototype (foam model) for the tangible validation of ergonomics (size, grip, stability) and internal component capacity prior to detailed 3D design.

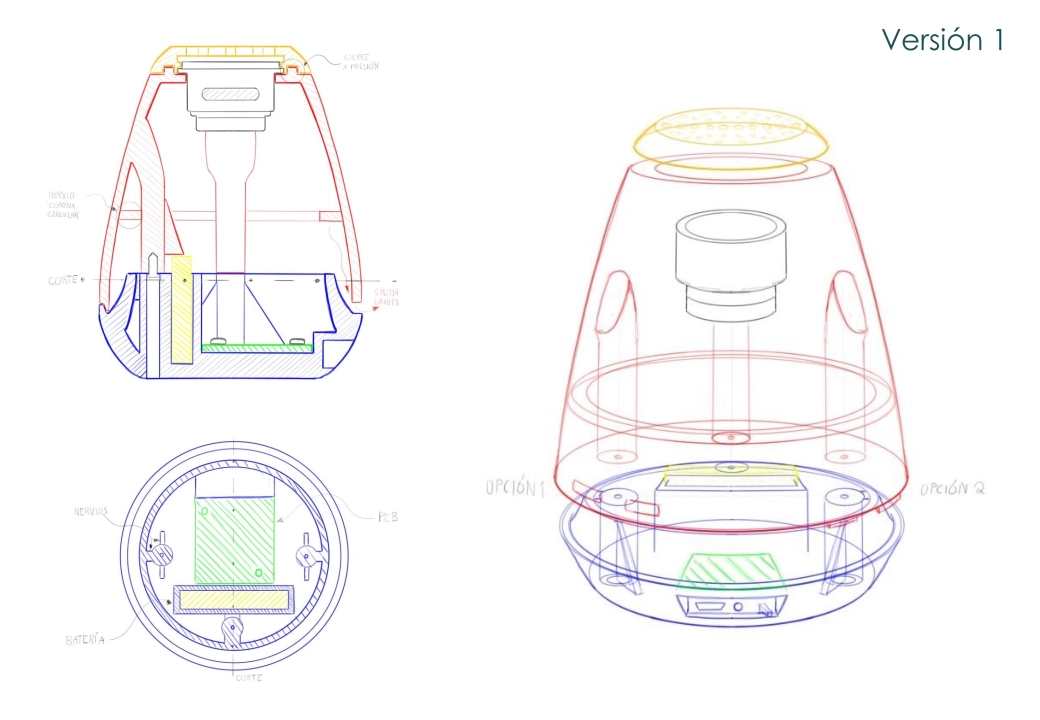

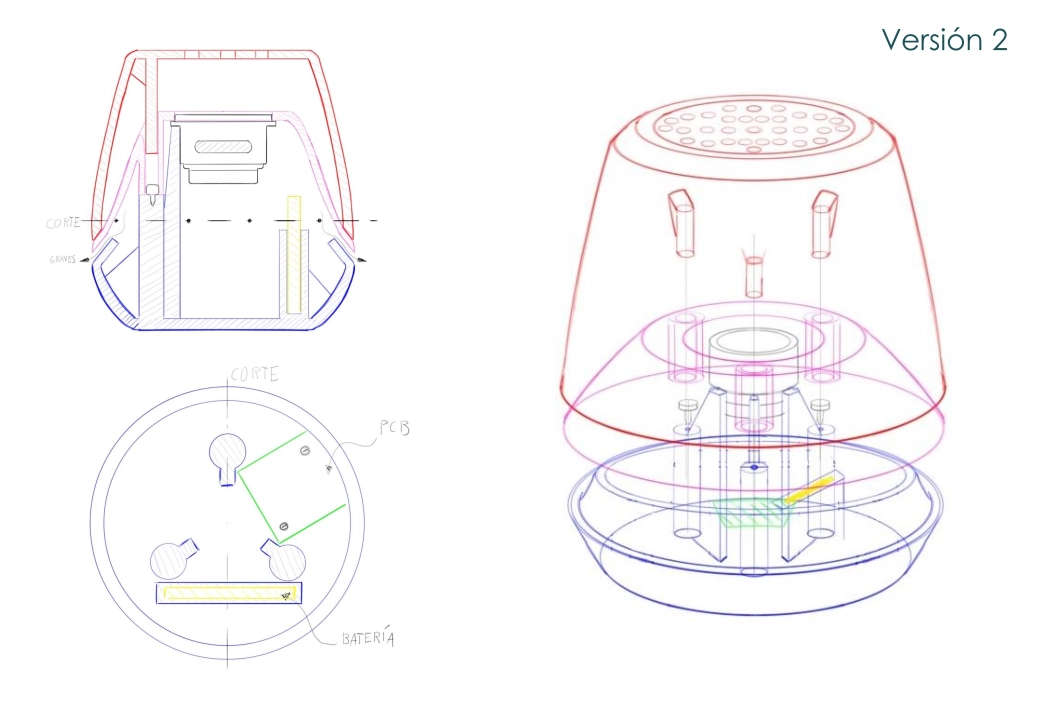

3. Detail Design & 3D Modelling

Definition of engineering specifications and internal structure, including 3D modeling of complex parts (e.g., battery placement and air intakes) and the creation of assembly drawings to ensure a feasable assembly.

4. Functional Prototyping & CMF Application

3D printing of final parts, surface preparation and finishing (CMF Application) for realistic presentation, and final assembly of all components to validate functionality and technical viability.